This guide offers a deep dive into the world of bulk beef purchasing and processing, revealing key factors that influence yield from the breed to the butchering process.

When purchasing beef in bulk, consumers frequently ask about the expected yield—how much meat they will actually take home after the animal is processed. Understanding the process and what factors influence the yield is crucial for anyone considering bulk beef purchasing. This article, based on a video by The Bearded Butchers, delves into the scientific aspects of yield percentage, the butchering process, and provides insight into what to expect when filling out cutting instructions.

Beef yield is influenced by several factors starting with the livestock breed. Dairy breeds, for example, tend to have more bone and less muscle as their nutrition primarily goes into milk production. Conversely, beef breeds like Angus are known for higher quality muscle mass. The muscle-to-fat ratio also affects yield, with more muscle and less fat being ideal for a higher yield.

When an animal is slaughtered, it loses a percentage of its initial live weight due to blood, gut content, hide, and other non-edible parts being removed. This leaves the hot carcass hanging weight, which is what customers typically pay for. State and industry regulations oversee this weighing process. The carcass then undergoes a dry aging period, which results in moisture loss—further reducing weight but enhancing flavor and tenderness.

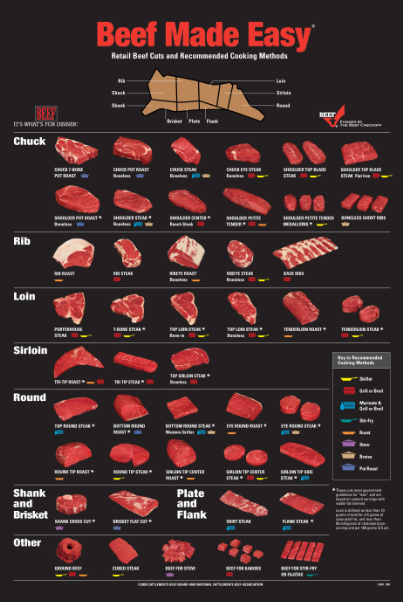

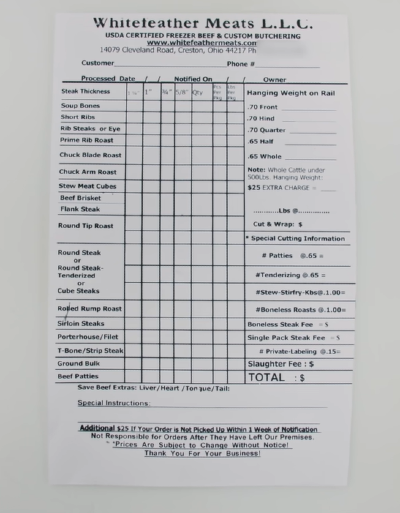

The butchering process involves breaking down the carcass into various cuts. The standard cuts come from primal sections, and choices have to be made between options like bone-in and boneless. A cut sheet or blueprint guides the butcher through these customizations.

A typical beef carcass can yield approximately 60% of its hanging weight as edible meat, although this varies. The type and number of steaks, roasts, and ground beef are determined by the initial instructions given. For instance, steaks can be cut to different thicknesses, affecting the overall number of steaks obtained. Similarly, roasts can be portioned into various weights, impacting the quantity.

Custom cutting instructions are crucial for tailoring the beef to personal preferences. These instructions should specify the desired cuts and their specifications, such as bone-in or boneless steaks, the thickness of cuts, and the division of meat into roasts, stew meat, and ground beef. Customers can also request a specific ratio of ground beef to patties based on their cooking habits.

To illustrate, a carcass weighing 390 pounds may have a dry-aged weight of 381 pounds after aging for approximately 15 days. If processed into a standard cut, the final yield would be around 60%, which in this case would be about 228.6 pounds of packaged meat. The remaining weight would account for bone, fat, and other trimmings removed during processing.

After processing, the meat is weighed and packaged. The final yield percentage is calculated by comparing the packaged weight to the original hanging weight. A 68% yield is considered excellent, indicating a lower amount of fat and bone waste.

Knowing what to expect when purchasing bulk beef is empowering for consumers. By understanding the factors that affect yield and actively participating in the cutting instruction process, customers can maximize the amount of meat they take home. This knowledge not only benefits consumers but also helps butchers provide better service by ensuring customers receive cuts that suit their needs and preferences. As the trend of buying freezer beef makes a comeback, being informed is more important than ever.